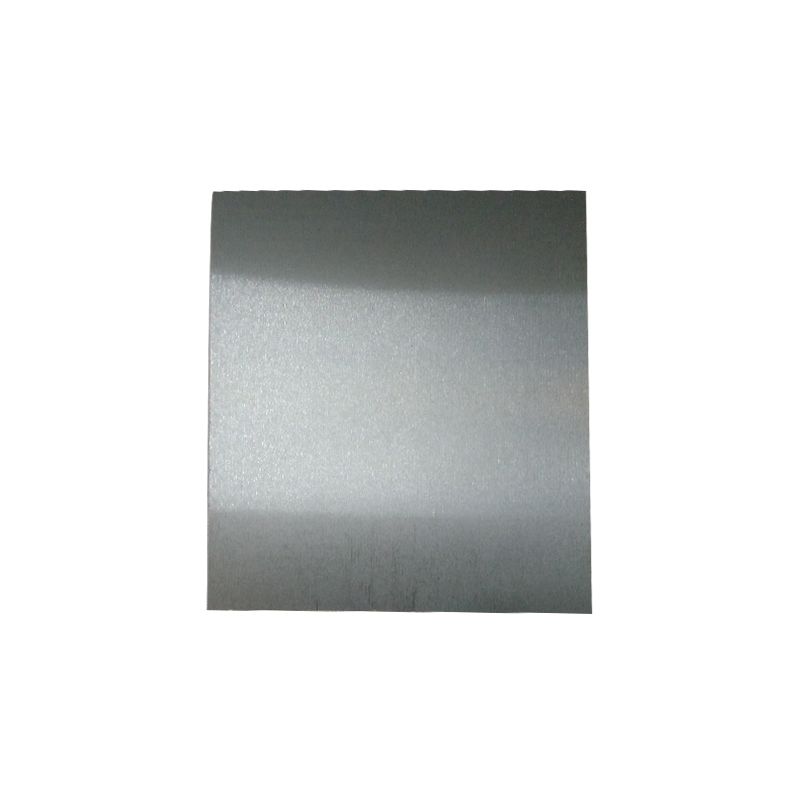

A molybdenum plate is a flat-rolled product made from high-purity molybdenum metal. It is widely used in high-temperature, high-stress, and corrosive environments due to molybdenum’s exceptional melting point, strength retention at elevated temperatures, and resistance to thermal creep. Molybdenum plates are typically produced through powder metallurgy, hot rolling, and controlled annealing to achieve the required mechanical and dimensional properties.

Compared with many other refractory metals, molybdenum offers a balance of high-temperature performance, machinability, and cost efficiency. This makes molybdenum plate a practical choice for industrial furnaces, semiconductor equipment, aerospace components, and energy-related systems.

Key Physical and Mechanical Properties

The performance of molybdenum plate is driven by its unique combination of physical and mechanical characteristics. These properties allow it to operate reliably in environments where conventional steels and superalloys may fail.

- Melting point approximately 2,623°C, enabling extreme high-temperature use.

- High modulus of elasticity for structural rigidity.

- Low thermal expansion to maintain dimensional stability.

- Good thermal conductivity for heat distribution.

These properties make molybdenum plate suitable for applications requiring precise thermal control, mechanical integrity, and long service life at elevated temperatures.

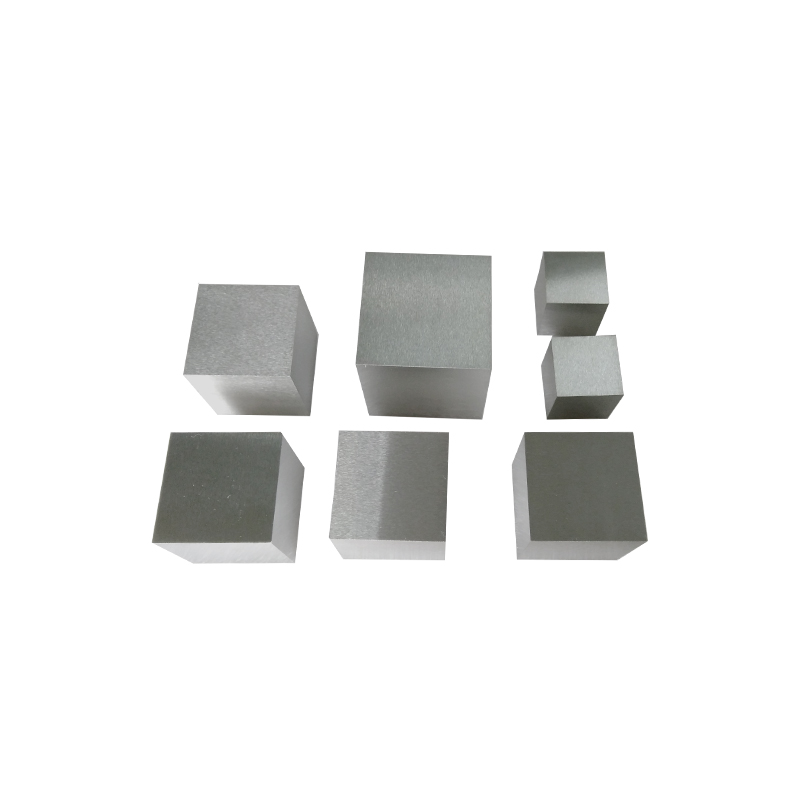

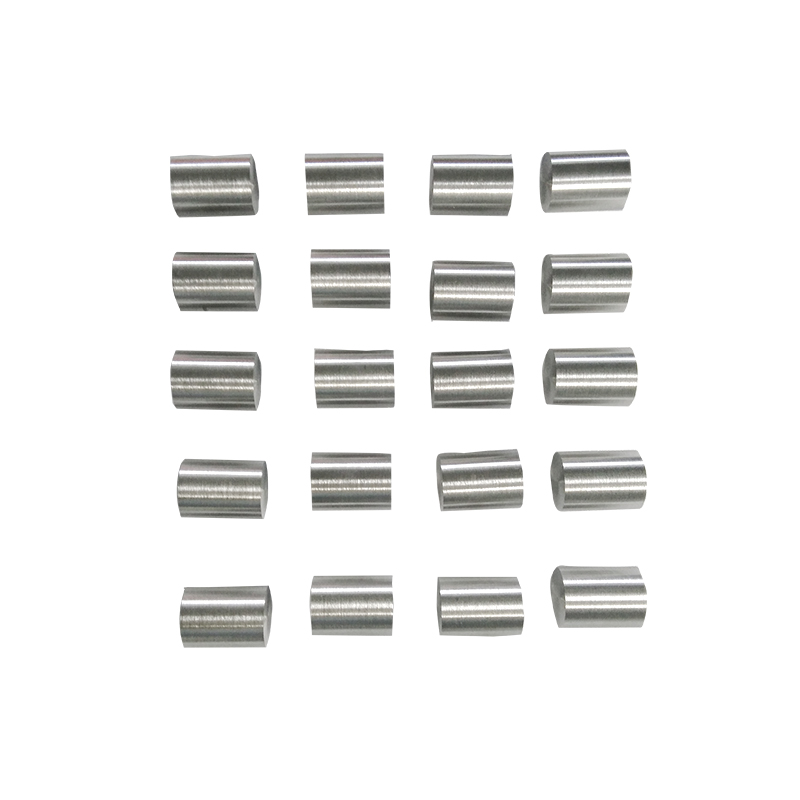

Common Grades and Purity Levels

Molybdenum plates are available in various grades depending on purity and alloying additions. The most common products are based on high-purity molybdenum, while specialty grades incorporate small amounts of alloying elements to improve specific performance aspects.

Pure Molybdenum (Mo ≥ 99.95%)

High-purity molybdenum plate is widely used in vacuum furnaces, semiconductor manufacturing, and laboratory equipment. High purity improves resistance to embrittlement and enhances performance in vacuum and controlled atmospheres.

TZM Alloy

TZM is a molybdenum-based alloy containing titanium, zirconium, and carbon. This alloy offers higher creep resistance and strength at elevated temperatures, making it suitable for hot tooling, die casting components, and high-stress furnace parts.

Lanthanum-Doped Molybdenum (ML)

Lanthanum oxide-doped molybdenum improves recrystallization temperature and high-temperature ductility. It is often selected for heating elements and components that require improved grain stability.

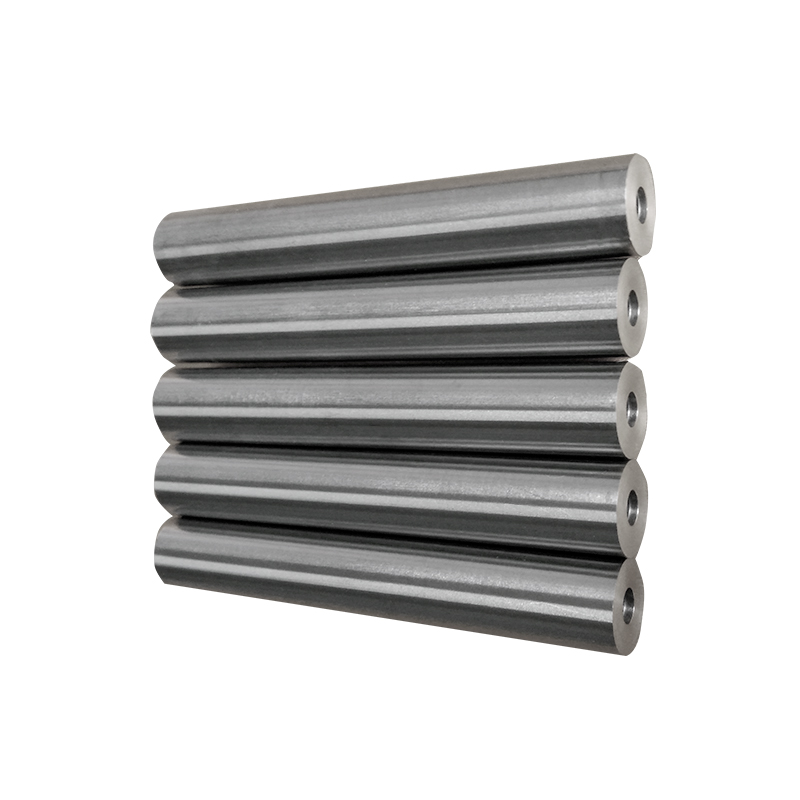

Manufacturing Process of Molybdenum Plate

Molybdenum plates are typically produced using powder metallurgy due to the metal’s extremely high melting point. The process begins with high-purity molybdenum powder, which is pressed into compacts and sintered to form dense billets.

These billets are then hot rolled and sometimes warm or cold rolled to achieve the required thickness and surface finish. Intermediate annealing steps are used to relieve internal stresses and refine the grain structure. Final surface finishing may include grinding, polishing, or chemical cleaning to meet tight dimensional and surface quality requirements.

Thickness Range and Dimensional Tolerances

Molybdenum plate is available in a wide range of thicknesses to support different industrial needs. Thin plates are used for electronic and semiconductor applications, while thick plates are used for structural and thermal shielding components.

| Thickness Range | Typical Use | Tolerance Level |

| 0.2 – 1.0 mm | Semiconductor parts | Tight |

| 1.0 – 5.0 mm | Furnace components | Standard |

| 5.0 – 50 mm | Structural and tooling | Custom |

High-Temperature Performance

One of the main reasons to select molybdenum plate is its ability to retain strength and dimensional stability at high temperatures. In vacuum or inert atmospheres, molybdenum can be used continuously at temperatures exceeding 1,500°C.

At elevated temperatures, molybdenum exhibits low creep rates compared with many alloys. This makes it suitable for load-bearing furnace fixtures, hot zones, and structural supports in thermal processing equipment.

Oxidation Behavior and Environmental Limits

While molybdenum performs well at high temperatures, it oxidizes rapidly in air at temperatures above approximately 400°C. The formation of volatile molybdenum oxides can lead to material loss and surface degradation.

To mitigate oxidation, molybdenum plates are typically used in vacuum, inert gas, or reducing atmospheres. In air-exposed environments, protective coatings or alloy alternatives may be required to extend service life.

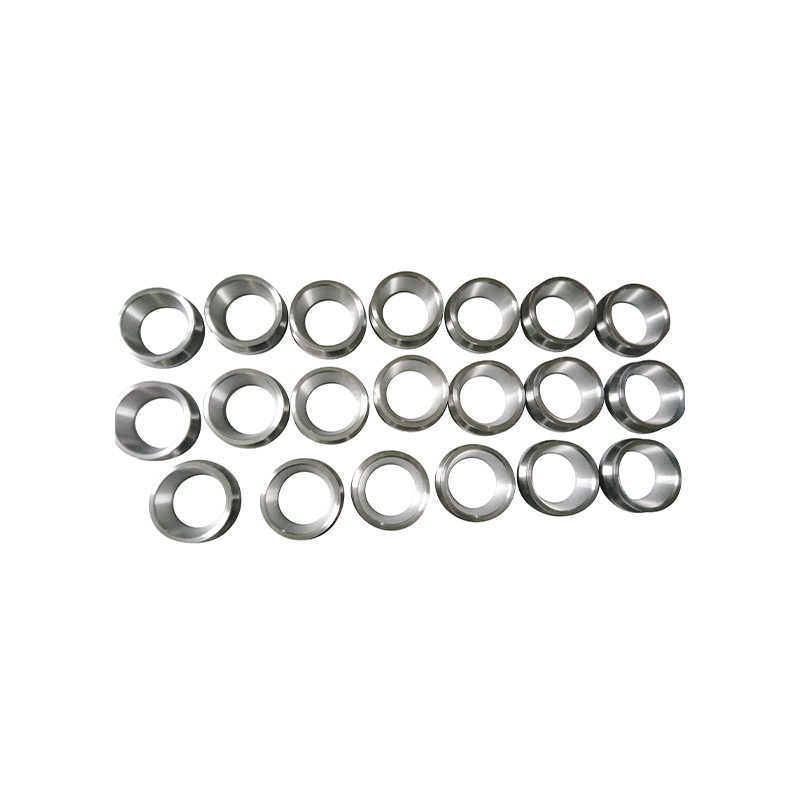

Machining and Fabrication Considerations

Molybdenum plate can be machined using conventional methods, but special care is required due to its hardness and brittleness at room temperature. Sharp cutting tools, controlled feeds, and proper cooling are essential to prevent cracking and tool wear.

Common fabrication methods include milling, drilling, waterjet cutting, EDM, and laser cutting. Preheating thicker plates can help reduce thermal shock and improve machining stability.

Joining and Assembly Methods

Joining molybdenum plates requires careful selection of methods to avoid contamination and embrittlement. Common techniques include mechanical fastening, brazing, and diffusion bonding.

Welding is possible but challenging due to molybdenum’s high melting point and sensitivity to oxygen and nitrogen. Welding operations typically require vacuum or inert gas shielding to prevent oxidation and cracking.

Applications in Semiconductor and Electronics

In the semiconductor industry, molybdenum plate is used for sputtering targets, electrode plates, heat spreaders, and structural components in vacuum chambers. Its low vapor pressure and thermal stability make it suitable for high-vacuum environments.

Precision thickness control and surface finish are critical in these applications, as even minor variations can affect process consistency and device performance.

Use in Furnace and Thermal Equipment

Molybdenum plate is widely used in high-temperature furnaces as heat shields, support plates, and hot zone structures. Its strength at temperature and low thermal expansion help maintain alignment and structural integrity.

In vacuum and hydrogen furnaces, molybdenum plates provide long service life and stable thermal performance, reducing downtime and maintenance costs.

Aerospace and Energy Applications

In aerospace and energy sectors, molybdenum plates are used in thermal barriers, high-temperature tooling, and specialized structural components. Their ability to withstand extreme temperatures and thermal cycling makes them suitable for demanding environments.

In nuclear and fusion-related research, molybdenum is sometimes selected for plasma-facing components and shielding applications due to its high melting point and low sputtering yield.

Quality Control and Inspection Standards

Quality control for molybdenum plate focuses on chemical composition, mechanical properties, and dimensional accuracy. Common inspections include chemical analysis, ultrasonic testing, and surface inspection.

- Chemical purity verification to ensure low impurity levels.

- Thickness and flatness measurements.

- Surface defect inspection for cracks and inclusions.

- Mechanical testing for strength and ductility.

Strict quality control ensures reliable performance and reduces the risk of failure in critical applications.

Packaging, Handling, and Storage

Proper packaging and storage are essential to prevent surface damage and contamination. Molybdenum plates are typically packed in clean, moisture-resistant materials to protect against oxidation and physical damage.

During handling, care should be taken to avoid bending thin plates and scratching finished surfaces. Clean gloves are often recommended to prevent oil and moisture transfer.

Cost Factors and Procurement Tips

The cost of molybdenum plate is influenced by raw material prices, purity level, alloy grade, thickness, and processing requirements. Custom sizes, tight tolerances, and special surface finishes increase overall cost.

When sourcing molybdenum plate, buyers should clearly specify grade, purity, thickness tolerance, flatness, and intended application. Requesting material certifications and test reports helps ensure compliance with technical requirements.

Conclusion: Selecting the Right Molybdenum Plate

Molybdenum plate is a critical material for high-temperature and high-performance applications. Its unique combination of thermal stability, strength, and dimensional control makes it indispensable in industries such as semiconductors, furnace manufacturing, aerospace, and energy.

By understanding grades, processing methods, environmental limitations, and quality requirements, engineers and buyers can select the most appropriate molybdenum plate to achieve reliable performance, long service life, and optimized total cost of ownership.